Wire Electrical Discharge Machining (EDM) is one of the greatest innovations affecting the tooling and machining industry. This process has brought dramatic improvements to industry in accuracy, quality, productivity, and earnings.

Before wire EDM, costly processes were often used to produce finished parts. Now, with the aid of a computer and wire EDM machines, extremely complicated shapes can be cut automatically, precisely, and economically, even in materials as hard as carbide.

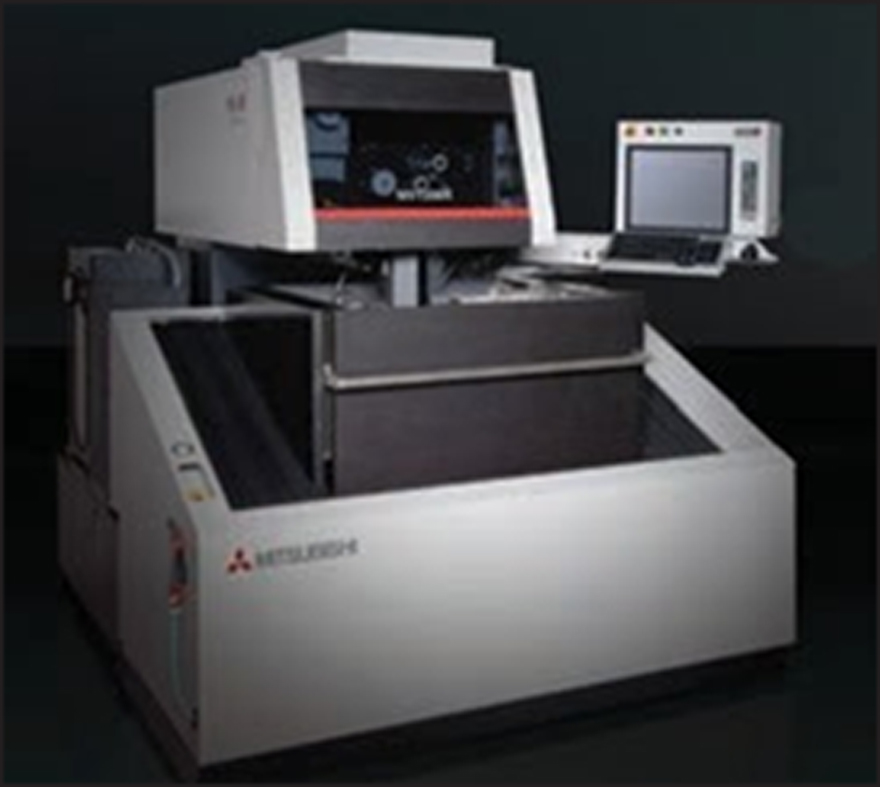

In 1969, the Swiss firm Agie produced the world’s first wire EDM machine. Typically, these first machines in the early ’70s were extremely slow, cutting about 2 square inches an hour (21 mm2/min.). Their speeds went up in the early ’80s to 6 square inches an hour (64 mm2/min.). Today, machines are equipped with automatic wire threading and can cut over 20 times faster than the beginning machines. A remarkable turnaround.

Whether cutting soft aluminum, hot rolled steel, super alloys, or tungsten carbide, manufacturers are discovering it is less expensive and they receive higher quality with today’s high-speed wire EDM machines for many production parts.

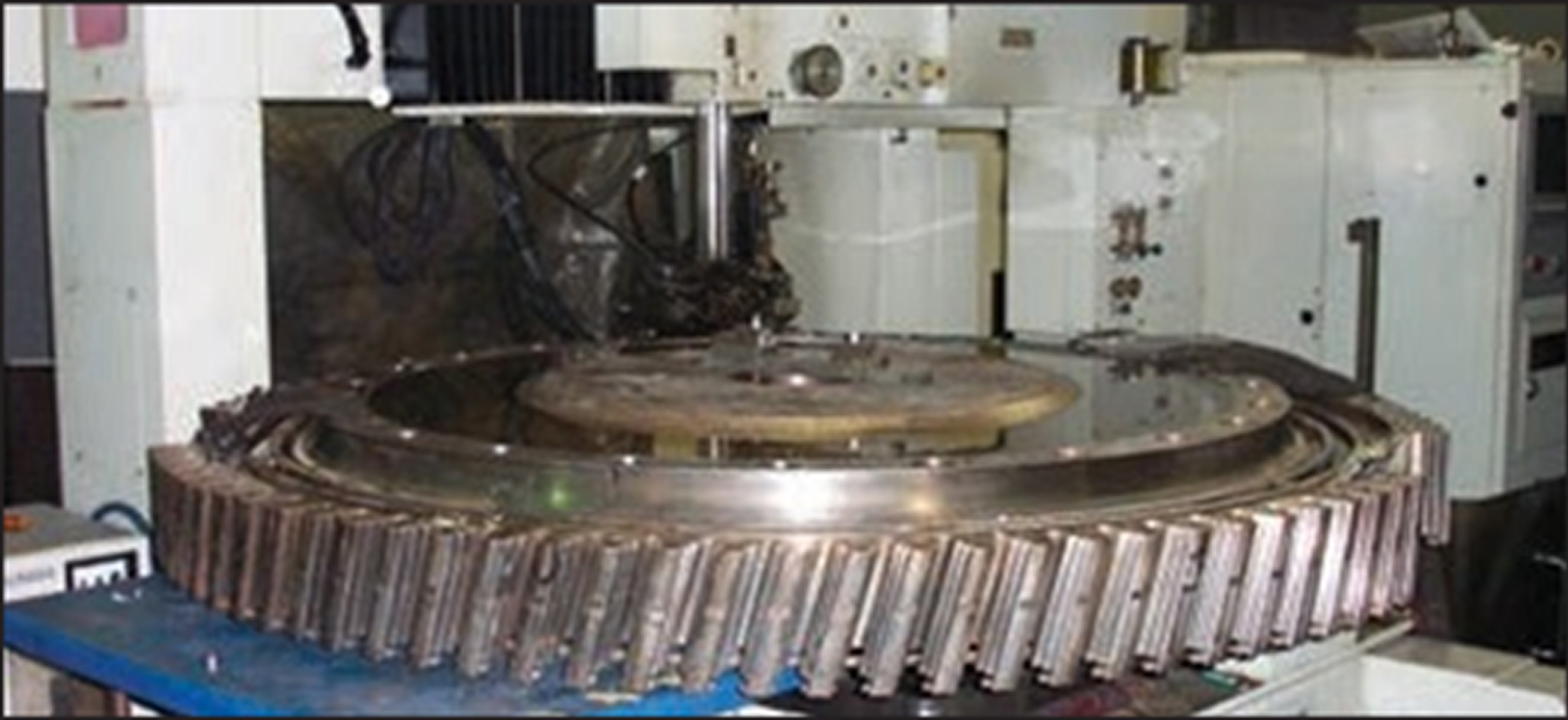

Some machines cut to accuracies of up to +/- .0001″ (.0025 mm), producing surface finishes to 12 rms. At our company, we can cut parts weighing up to 10,000 pounds.

Today, wire EDM competes seriously with such conventional machining as milling, broaching, grinding, and short-run stamping. Conventional wisdom suggests that wire EDM is only competitive when dealing with expensive and difficult-to-machine parts. But this is not the case. Wire EDM is often used with simple shapes and easily machined materials. Our company receives much work that could be machined by conventional methods. Although many of the customers have conventional CNC machines, they send their work to us to be EDMed.

A large wire EDM company reports their production runs up to 30,000 pieces take 65% of their cutting time. One particular job of theirs would have required fine blank tooling and a 10-12-week wait, but EDM was able to finish the hardened .062″ (1.57 mm) thick stainless steel parts burr-free and on time for their production schedule.

As more design engineers discover the many advantages of wire EDM, they are incorporating new designs into their drawings. Therefore it becomes important for contract shops to understand wire EDM so they can properly quote designs requiring EDM.

An added benefit of wire EDM is that exotic alloys can be machined just as easily as mild steel. When wire EDM manufacturers select the optimum steel to demonstrate the capability of their machines, their choice is not mild steel, but hardened D2, a high-chrome, high-carbon tool steel.

Increasingly, today’s drawings are calling for tighter tolerances and shapes that can be only efficiently machined with wire EDM.

For total unattended operation, some wire EDM machines are equipped with automatic wire threading and robotized palletization. These machines are well equipped to do high production runs.

One company making standard and made-to-order punch and die sets for turret punch presses uses numerous wire EDM machines fed by a robot. The robot moves on a track between the two rows of wire EDM machines. After the parts are EDMed, a non-contact video inspection system, interfaced with a computer system, automatically examines the work.

General Electric uses 36 wire EDM machines to cut steam turbine bucket roots. Previously, GE used as many as 27 different operations, many of them milling; now it can cut the entire bucket periphery in one pass. Prior delivery with conventional methods required 12 weeks; wire EDM reduced the delivery to 2-4 weeks.

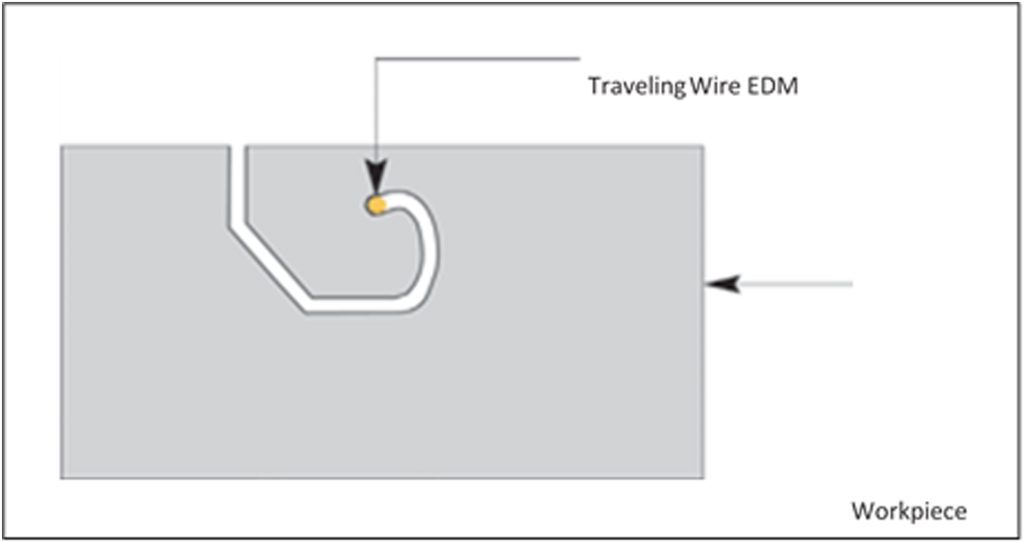

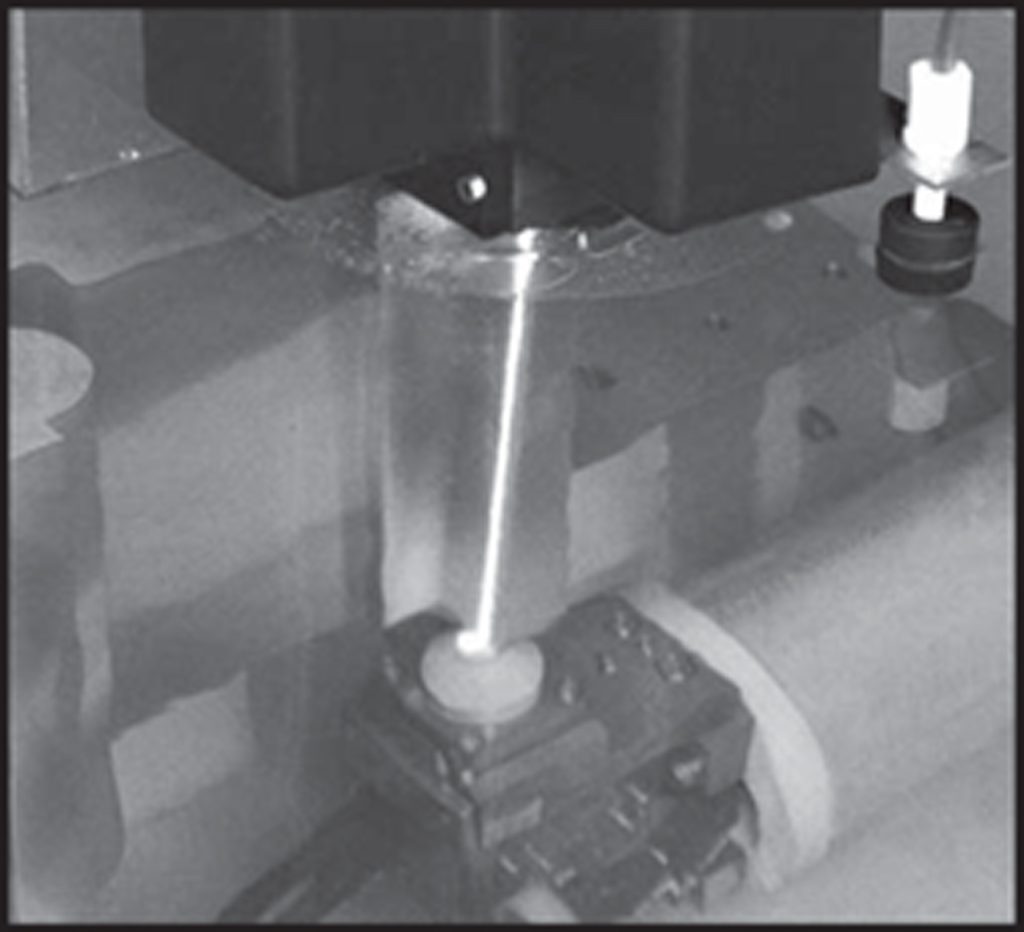

Wire EDM uses a traveling wire electrode that passes through the work piece. The wire is monitored precisely by a computer-numerically controlled (CNC) system.

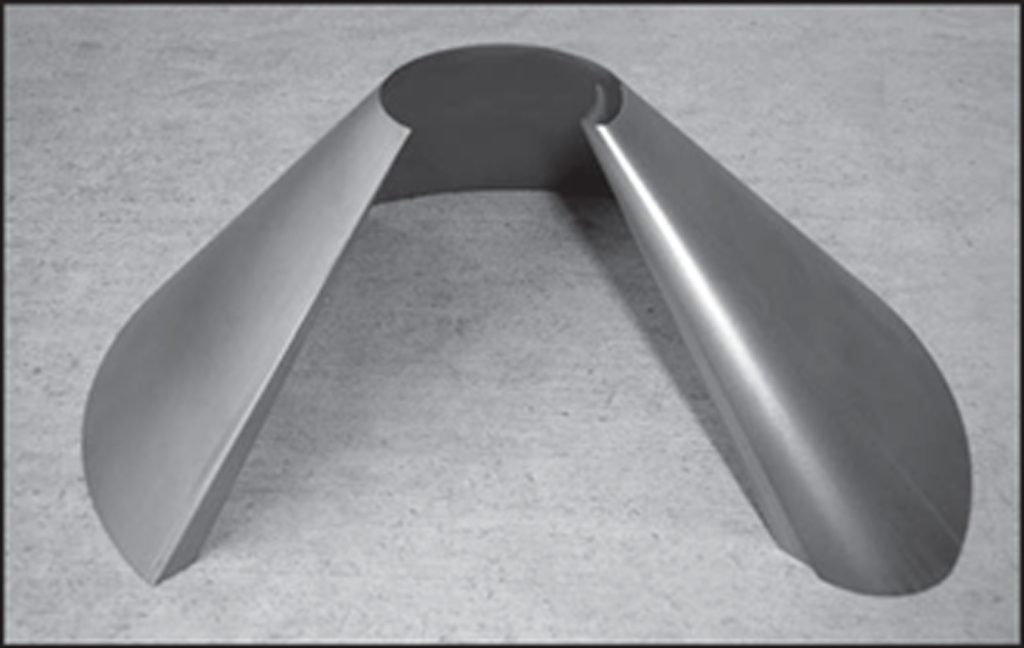

Manufacturers have discovered unique ways of using the capabilities of the independent four axis: extrusion molds, flow openings, injection molds, and many other complex shapes.

To better understand independent four axis, a person can hold a string and move the top and bottom of the string independently. Virtually any conceivable shape can be created within the confines of the travel of the U and V axis of the wire EDM machines. Machines are capable of cutting tall parts with independent angles up to 45 degrees.

Wire EDM Machines are Capable of Cutting 45° Angles.

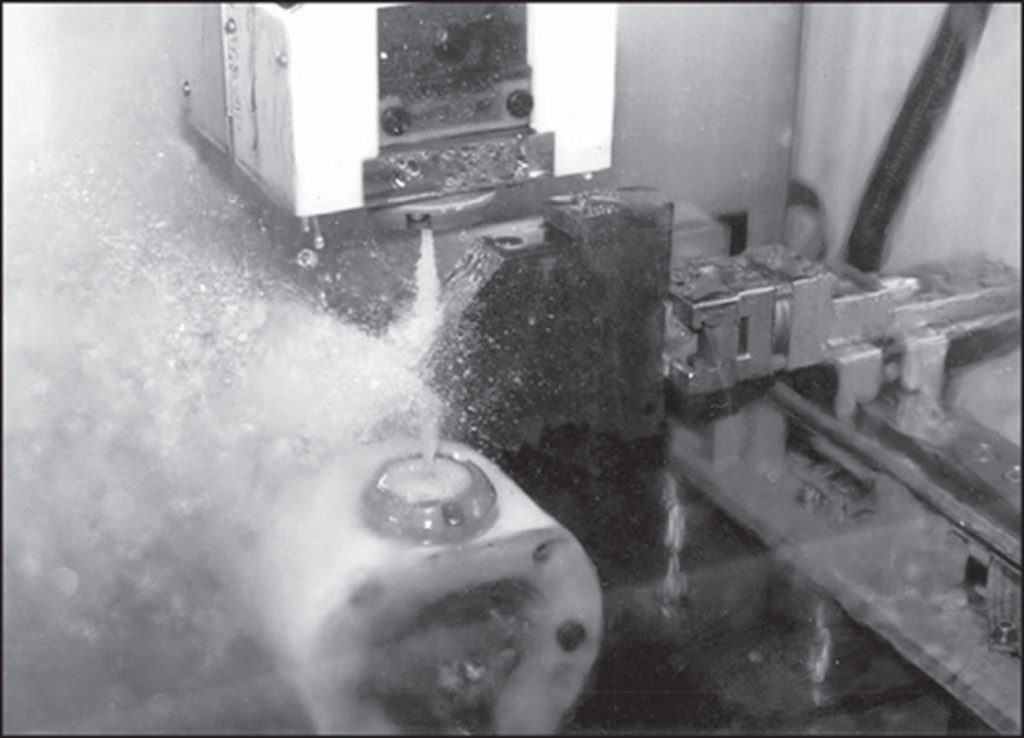

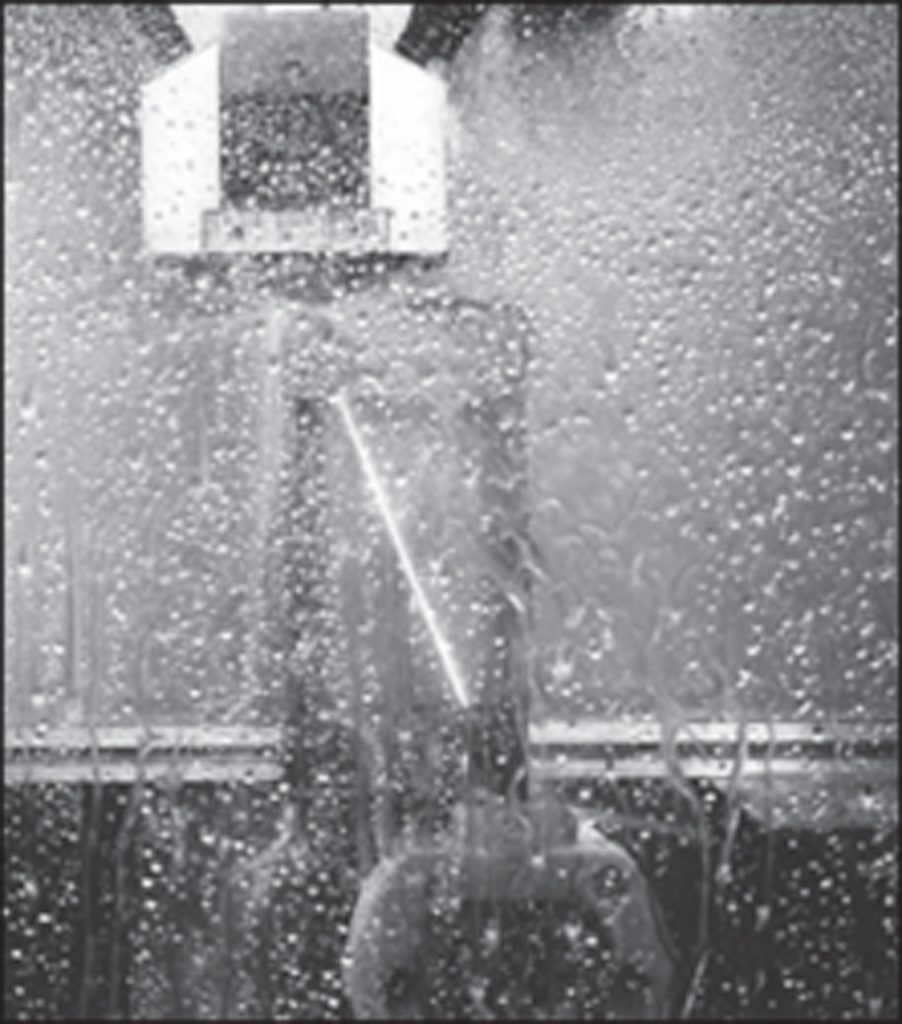

In submersible cutting, a tank surrounds the work area, and the tank is filled with deionized water before the cutting takes place. In a dry machine, water needs to flow from the nozzles to surround the wire with deionized water.

Submersible cutting is a great aid in starting a cut and when skim cutting because the wire is always submersed in water, as shown in Figure 2:22. Dry machines can also do skim cutting, but one needs to be careful of always maintaining water around the wire, otherwise the wire will break.

To remain successful, companies need to keep informed of the newest technologies in order to remain competitive. Understanding the many changes in the EDM processes is important for those in manufacturing.

Engineering and trade schools should be concerned that their graduating students are properly equipped to enter the workforce knowing the latest technologies. This book aims to encourage and educate upcoming engineers, toolmakers, and those in management to understand and be able to use the EDM processes profitably.

In 1981, someone proved mathematically that wire EDM could not achieve speeds over 4 sq. in. (43 mm/min.) per hour. Those who experienced wire EDM in the early ’80s may have decided that this process was inefficient and costly. Times have changed EDM dramatically.

The first wire EDM machines had heights between 2 to 4 inches (51 mm to 102 mm). Through the years, the cutting heights of EDM machines have increased. A customer came to Reliable EDM with a tall part and was told we couldn’t cut the part because of the height limitations of our machines. Carl Sommer happened to pass by as the customer was told they could not cut the part. Since Carl has years of machining experience and has worked on building machines, he thought they could modify a machine to cut the part. Today, they can EDM parts weighing up to 10,000 pounds and workpieces up to 64 inches (1626 mm) tall. Illustrated in Figure 2:24 are some tall parts our company has EDMed. The moral of the story—let your imagination run wild.