Parts made with the wire EDM process are used for machining conductive materials for medicine, chemical, electronics, oil and gas, die and mold, fabrication, construction, automotive, aeronautics, space—virtually any place where electrically conductive materials are utilized.

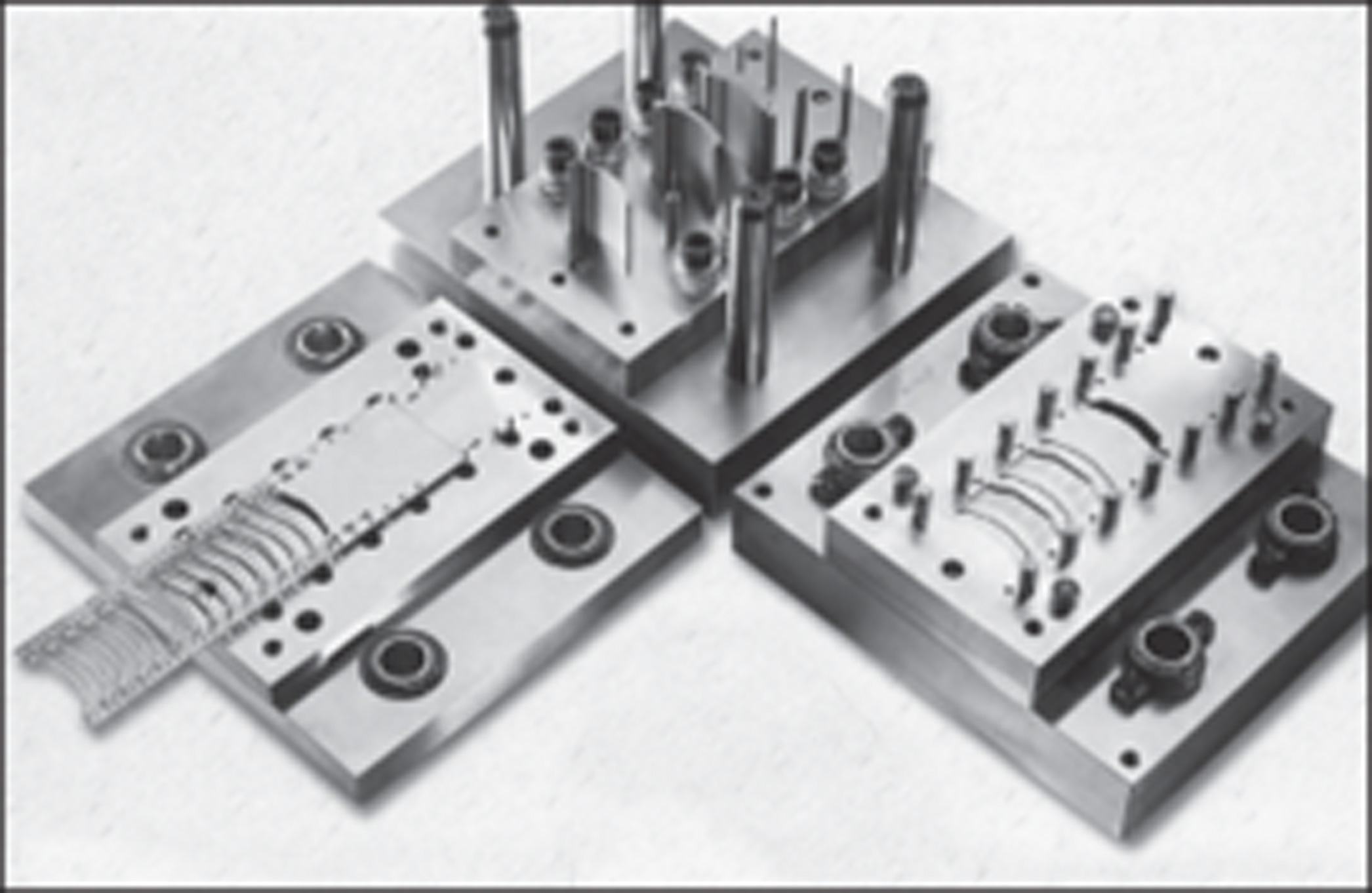

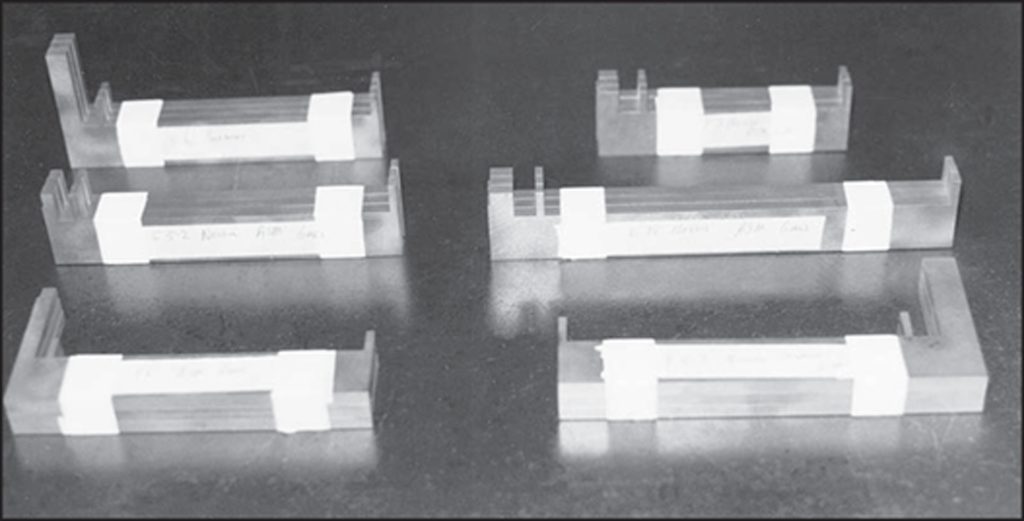

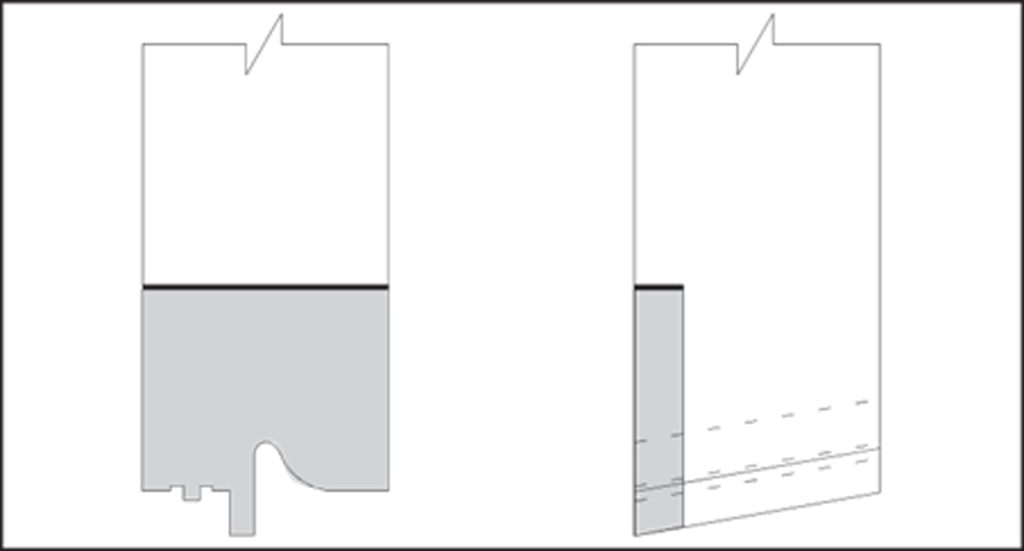

Because of the new generation of high-speed wire EDM machines, manufacturers increasingly are discovering that wire EDM produces many parts more economically than conventional machining. See Figure 3:1 and 2. An additional benefit with wire EDM is that close tolerances can be held without additional cost and without burrs.

With wire EDM technology, any contour and varying tapers can be machined precisely. Extremely thin sections can also be made because the wire electrode never contacts the material being cut. Wire EDM is a non-contact, metal-removing process which eliminates cutting stress and resultant mechanical distortion. If there is distortion, it is because of the stresses that were in the material being EDMed.

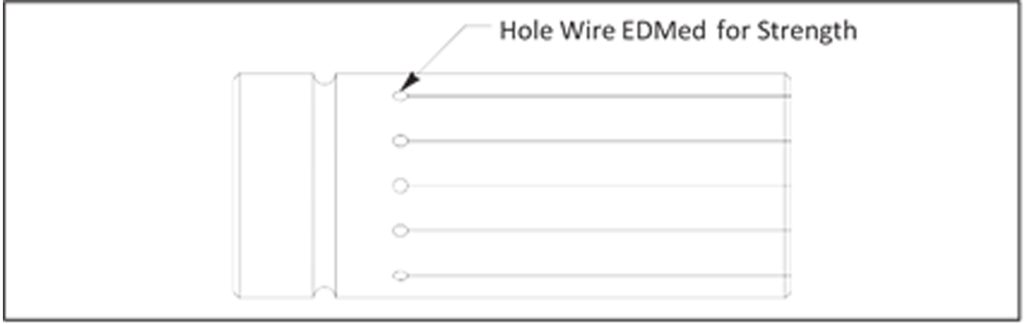

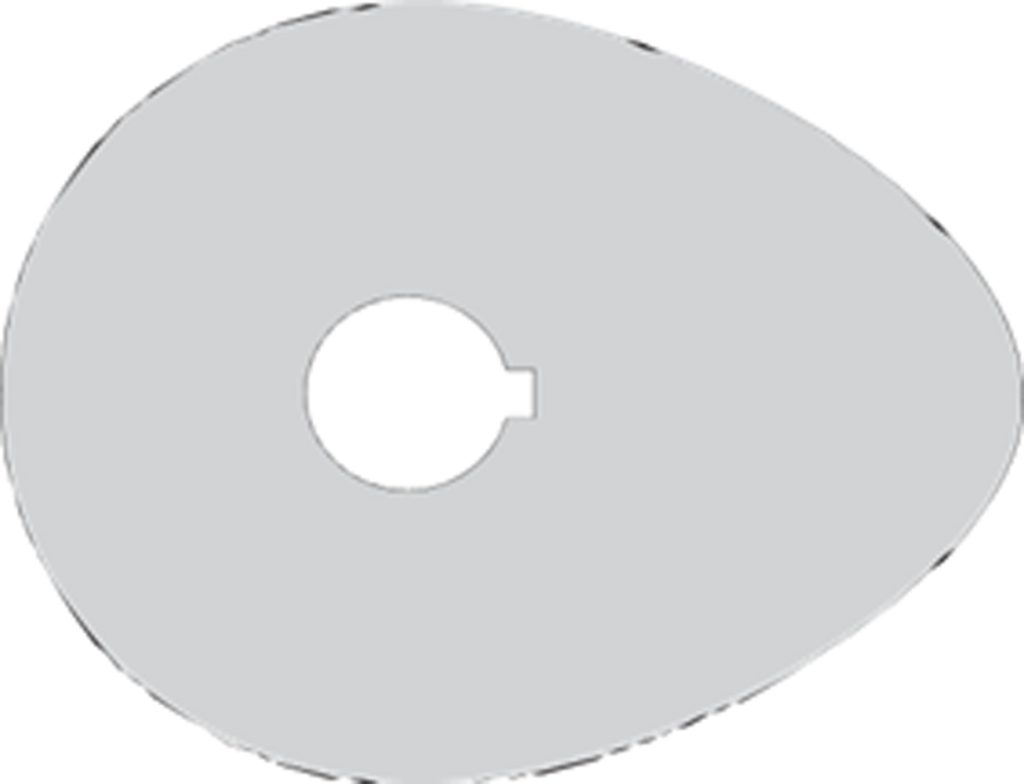

The wire path is controlled by a CNC computer-generated program with part accuracies up to +/- .0001″ (.0025 mm), and some machines achieve surface finishes well below 12 rms. Dowel holes can be produced with wire EDM to be either press or slip fit. See Figure 3:4, an example where precision cams were EDMed.

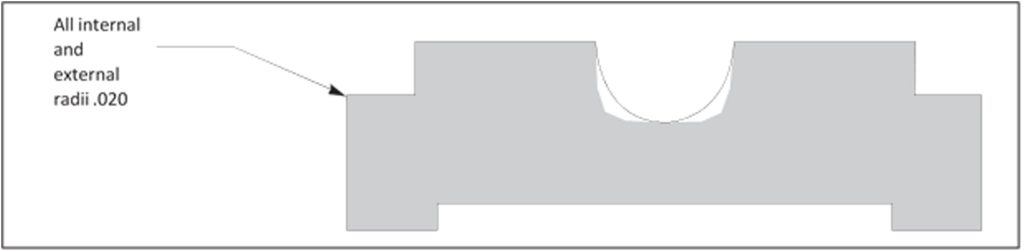

The extremely fine finish from the standard wire EDM process often eliminates the need for grinding or other finishing procedures. When using wire EDM, one should not hesitate to add small radii to eliminate a secondary operation, such as deburring of edges (Figure 3:5). The cost is unaffected by adding radii.

Stamped materials have rollover edges and tapers. Wire cut materials are totally burr free, smooth, and straight.

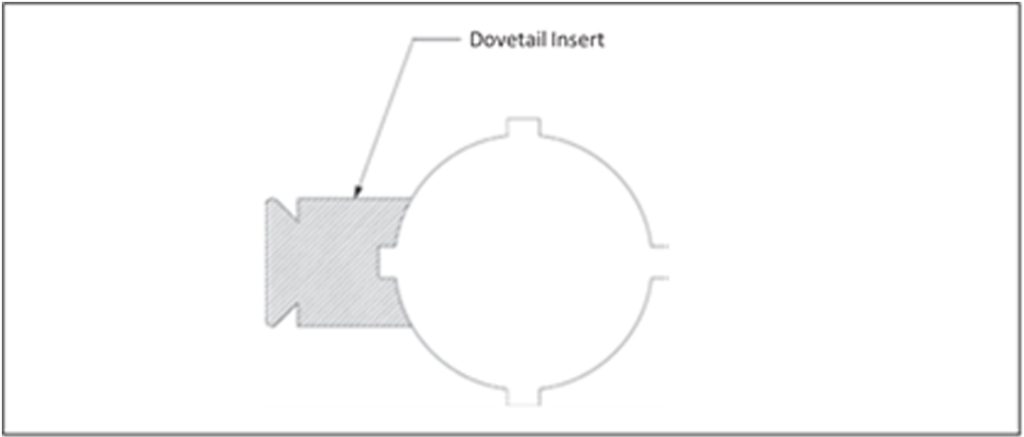

EDM allows a damaged die, mold, or machine part to be repaired with an insert rather than requiring the part to be remade. An insert can be EDMed and held with a screw, or a tapered insert can be produced so that it can be forced to fit.

Because wire EDM often eliminates extreme precision and time consuming machining processes, it reduces the need for skilled craftspersons. This frees such professionals for more productive and profitable work.

Wire EDM’s cutting ability is unaffected by workpiece hardness. In fact, it cuts hardened D2 faster than cold roll steel. The advantage of cutting materials in the hardened state is that it eliminates the risk of distortion created when the material needs to be heat treated.

EDM introduces minimal heat into the material, and the small amount of heat that is generated is quickly removed by the dielectric fluid. At our company we have EDMed hundreds of hardened stamping dies from various tool steels with no negative results.

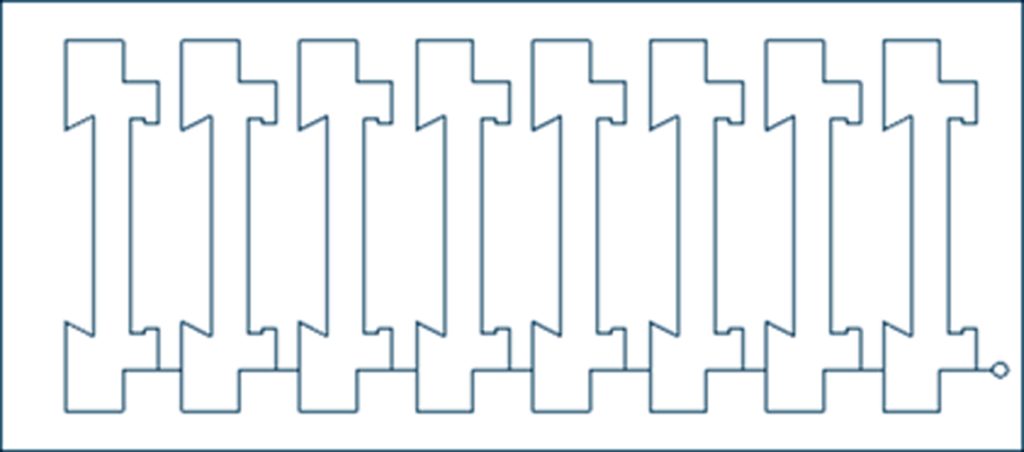

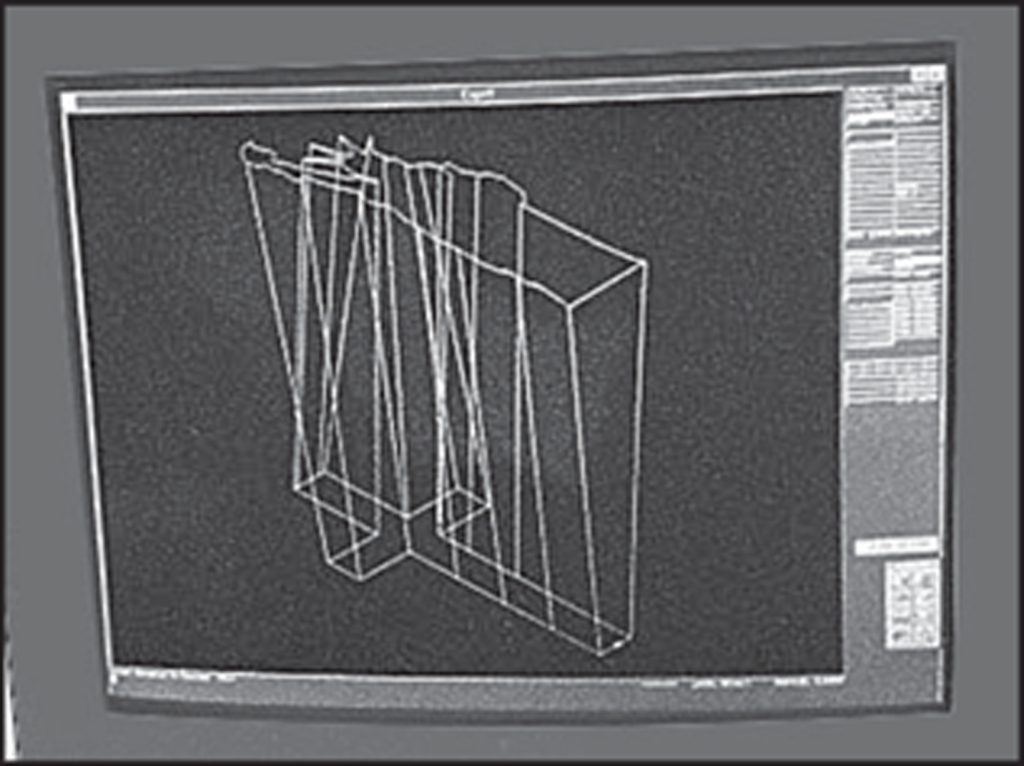

Since computers program the path for wire EDM, usually only basic math dimensions are needed. Also, when exact chord positions on blending radii are required, computer programs can automatically calculate the blending points. See Below Figure.

It is not always necessary to have exact dimensions of a drawing or of a part. By means of digitizing, as illustrated in Figure 3:10, a program can be made directly from a drawing or from a previously produced part.

Wire EDM can machine thin webs with extreme precision, and close inside and outside radii with fine micro finishes. Some micro wires range from 6.35″ (.25mm) to 5.08:” (.20mm). It needs to be pointed out, when very thin wires are used, it takes longer to EDM parts then with thicker wires.

Parts can be EDMed, even when flush nozzles are not directly against the workpiece. This is a slower cutting process due to less water pressure in the cut, but for many jobs it is still economical.

The reliability of wire EDM is one of its great advantages. Because programs are computer generated and the wire electrode is being fed constantly from a spool and used only once, the last part is identical to the first one. The cutter wear of conventional machining does not exist with wire EDM. Because of this, tighter machining tolerances can be maintained without additional costs.

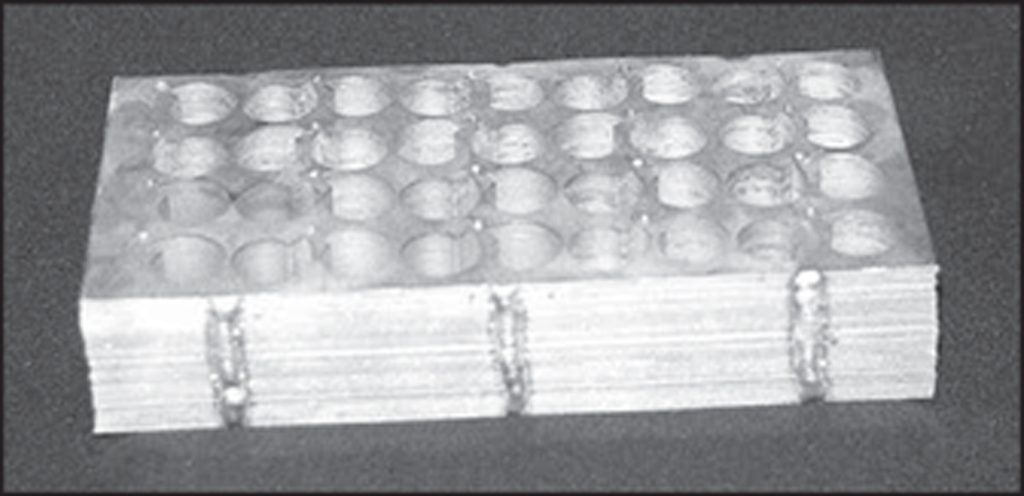

Computer generated programs for wire EDM are used rather than costly grinding procedures to produce precision gauges and templates, as in shown in Figure 3:13 and 14. Since gauges and templates are often thin, making two or more at the same time adds little to the cost of their production.

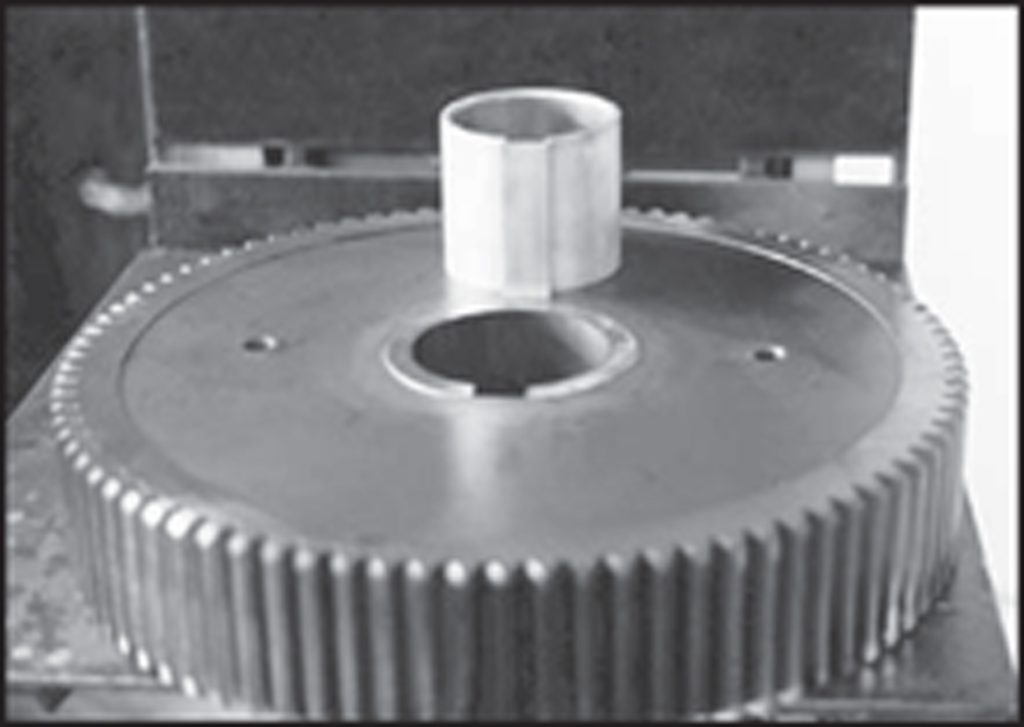

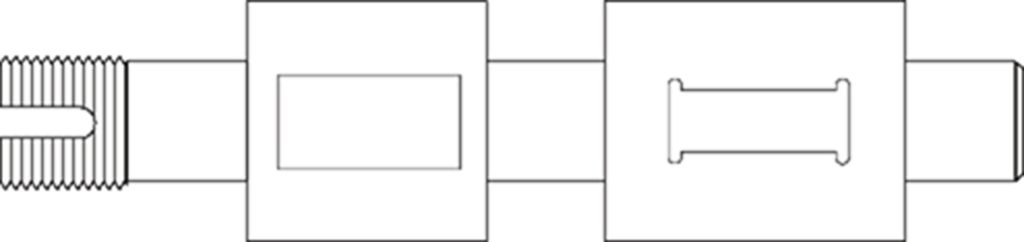

Wire EDM easily cuts precision keyways, as shown in Figure 3:15. It also produces hexes, splines, and other shapes, without the need to make special broaches, even from the material in the hardened state.

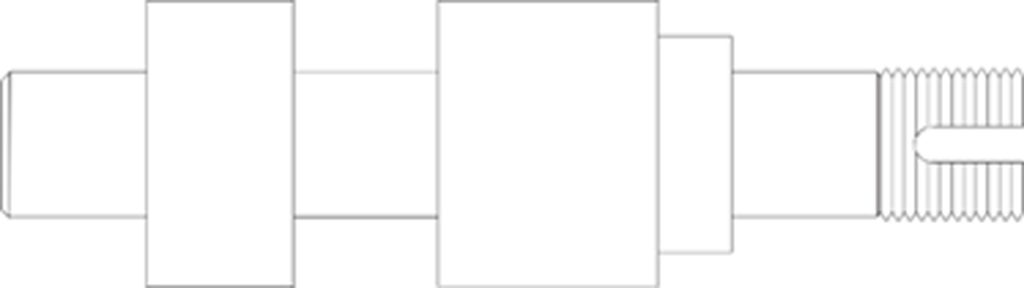

Rather than make a costly setup to machine a slot in a shaft, a simple setup can be made on a wire EDM machine. In addition to saving time, EDM produces no burrs in the threaded area.

Conventional machining often distorts collets. If the collets are heat treated after machining, they often distort even more. In contrast, wire EDM can machine collets in the hardened condition and without any cutting pressure, as shown in Below Figure.

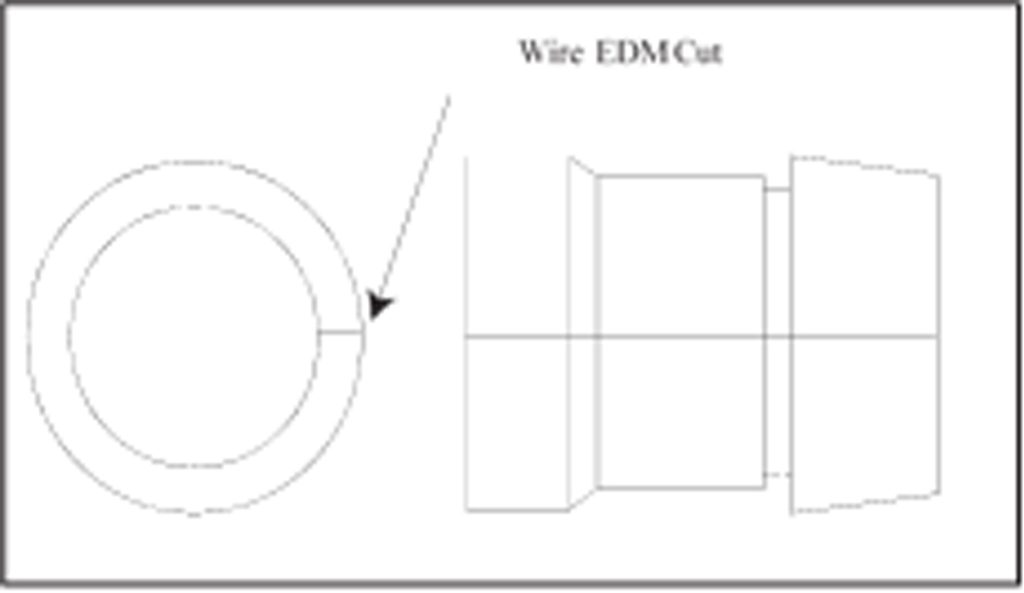

Because of the small gap produced by wire EDM—a .012″ (.30 mm) wire pro- duces a .016″ (.41 mm) gap (thinner wires can also be used)—tubes, shafts, and bearing cages can be parted after machining is completed, as pictured in Below Figure.

Any shaped pocket which goes through a shaft can be machined with wire EDM. See Below Figure.

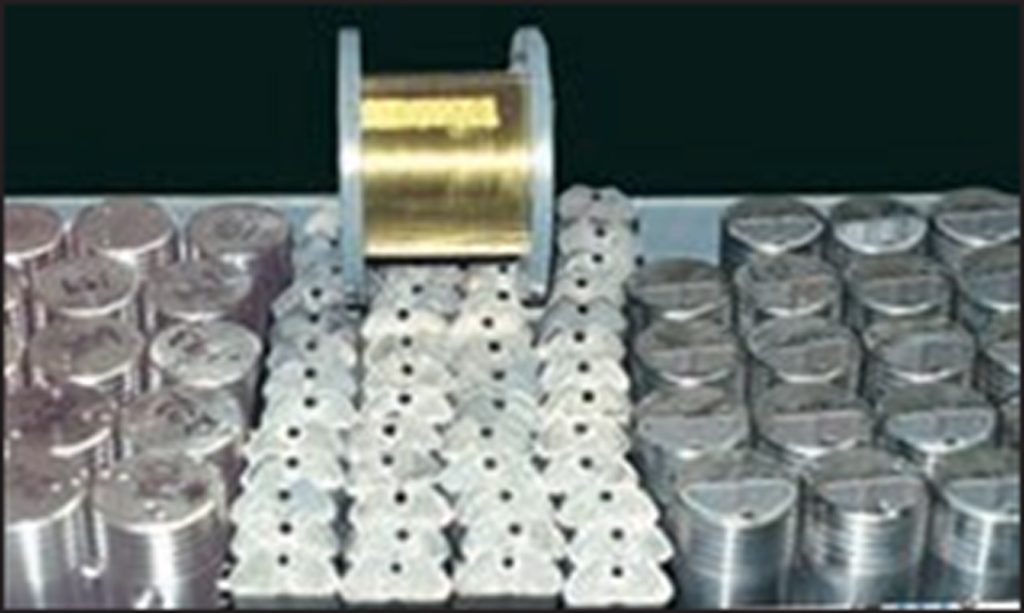

Graphite electrodes for ram EDM can be machined with wire EDM. One of the great advantages for this is that wire EDM produces identical electrodes.

The cost of producing graphite electrodes is largely determined by the cutting speed of the wire. The cutting speed of various grades of graphites are vastly different. For example, the graphite Poco Angstrofine, EDM-AF5, cuts nearly twice as fast as most of the other grades, EDM-1, EDM-3, EDM-100, or EDM 200.

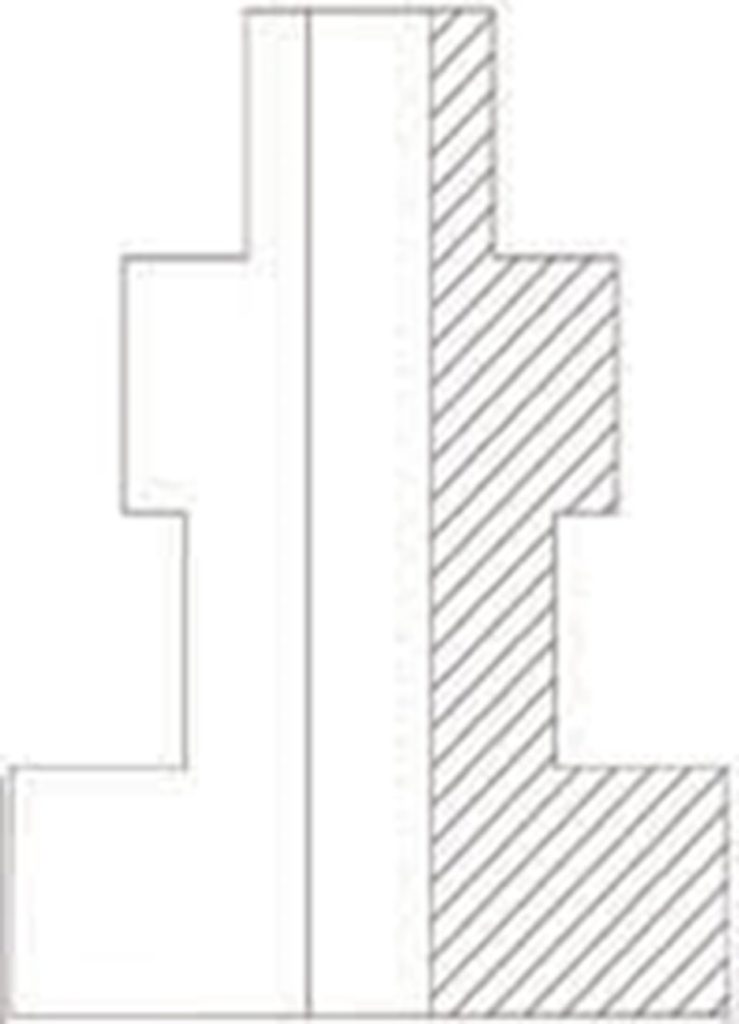

With wire EDM, dies no longer have to be made by the costly method of being sectioned and precision-ground. Now the most elaborate contours can be made from one solid piece of hardened tool steel.

The one-piece tool steel results in a stronger, non-breathing die at a fraction of the cost of a sectioned die. Also, compound dies can be wire EDMed from one piece of tool steel. For detailed instructions on EDMing and fabrication of these low-cost, high-performance one-piece dies.

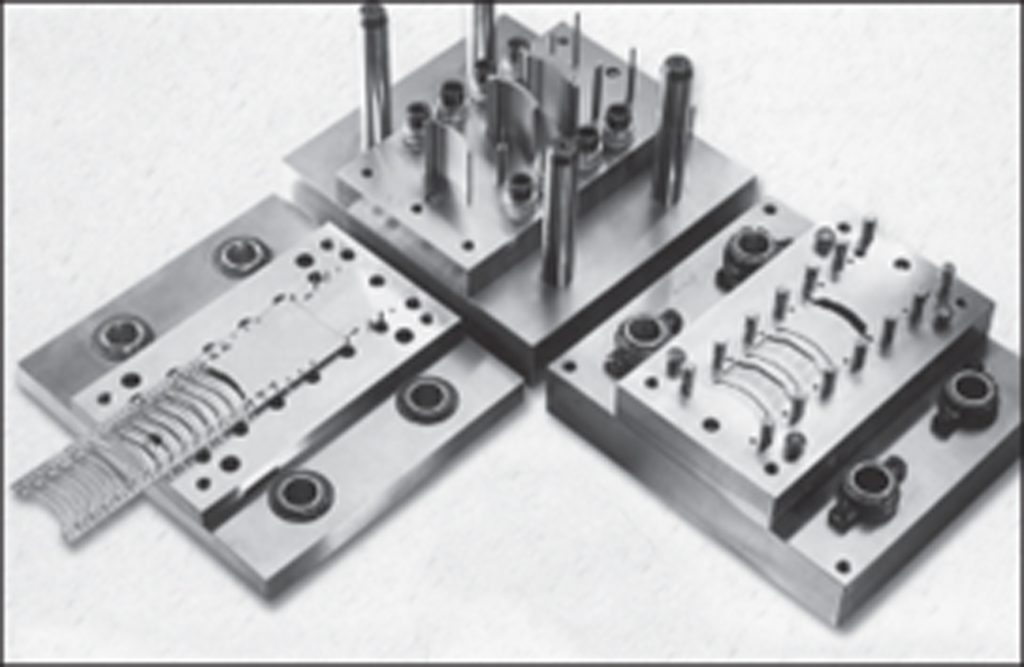

Wire EDM has dramatically altered progressive tool and die making, as illustrated in Below Figure. Now elaborate die sections can be precisely EDMed at a much lower cost.

Instead of expensive tooling being produced for short runs, precision parts can be produced with wire EDM. See Below Figure. When alterations are needed, they can be made at practically no cost; while alterations with hard tooling are usually costly. Wire EDM can also produce all sorts of special shapes and in various thicknesses.

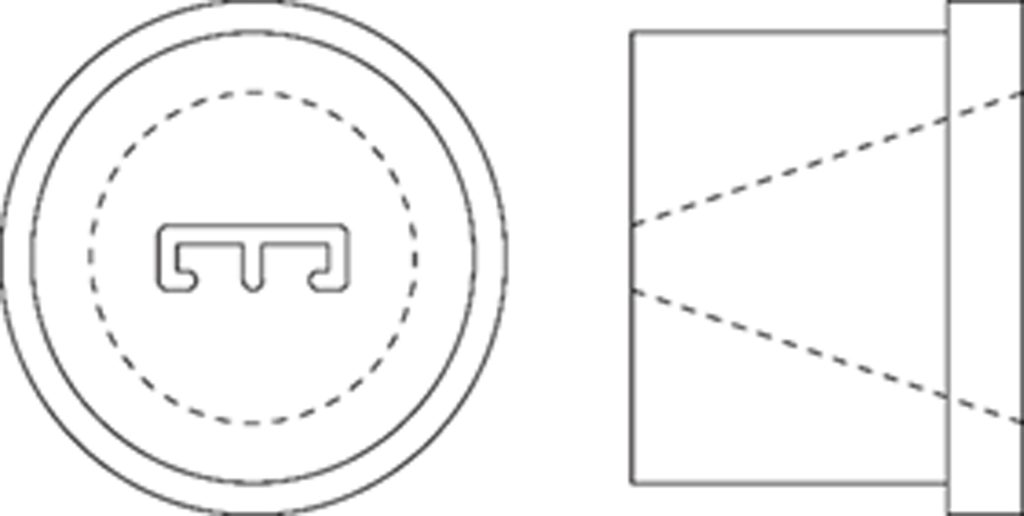

Elaborate extrusion molds, with or without, taper can be produced economically. See Below Figure.

Wire EDM can produce special one-of-a-kind tooling with various tapers, including carbide. See Below Figure. When production tool cutters need to be made, they should all be the same to eliminate costly setups and checking procedures when changing cutters. Since wire EDM repeats accurately, this process produces identical production tool cutters.

Wire EDM has dramatically reduced costs for many manufactured parts. Instead of using costly setups and complicated machining procedures to produce parts, wire EDM is often more cost effective. for a difficult production machining operation that could be produced more economically with wire EDM.

Many other parts can be also economically produced with wire EDM. Following are some samples. See Below Figures.

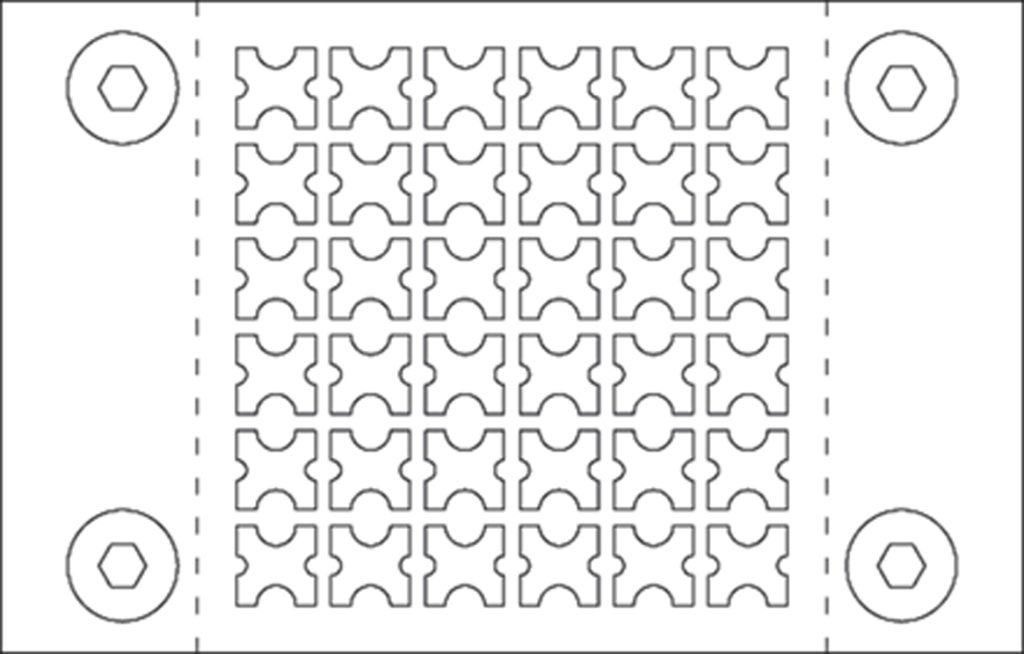

For most sheet metal parts, lasers are more cost efficient. However, when thin materials need to be cut without many holes, wire EDM can be significantly cheaper and produce an edge that is totally burr free. For example: 500 pieces to be machined from .005 shim stock. With wire EDM, the shim stock is cut and sandwiched between two 1/4 inch (6.4 mm) steel plates. The total height of the shims is 2.5 inches (63.5 mm). See Below Figure.

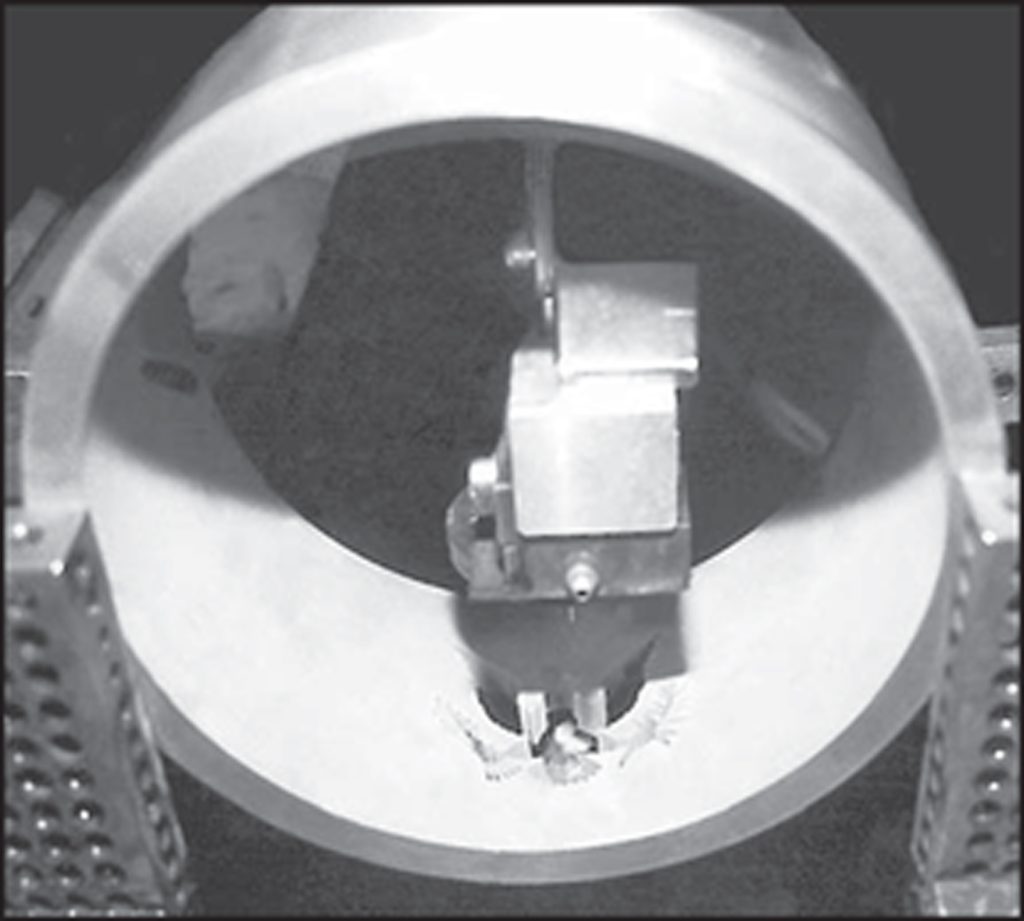

An oil field company needed two tapered cavities to be cut out of one side of a tube. A wire EDM machine is like a precision band saw. Under normal conditions, one cannot cut single cavities with a wire EDM machine. However, our company designed a special fixture that enabled us to cut 22″ deep (559 mm) into one side of a tube. Illustrated in Below Figures , is a show piece that we cut with our special fixture.

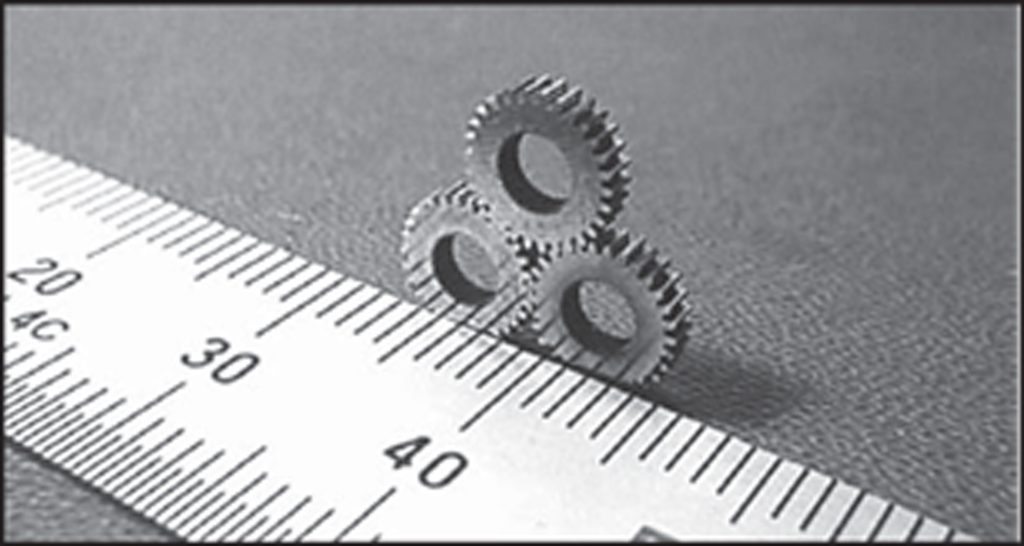

Some wire EDM machines can cut horizontally instead of vertically. See Below Figure. One of the machines uses wire as small as .00078″ (.02 mm). This machine is capable of automatically threading wire through a .0019″ (.05 mm) diameter hole. This type of a machine is used for micro-miniature molds, gears, fiber optics, motors, actuators, nozzles, and medical instruments. One of the big advantages of horizontal wire EDM is it is better adapted for automation because the slug can fall straight down and not interfere with cutting the next part. A sensor on the machine indicates that the core has been removed.

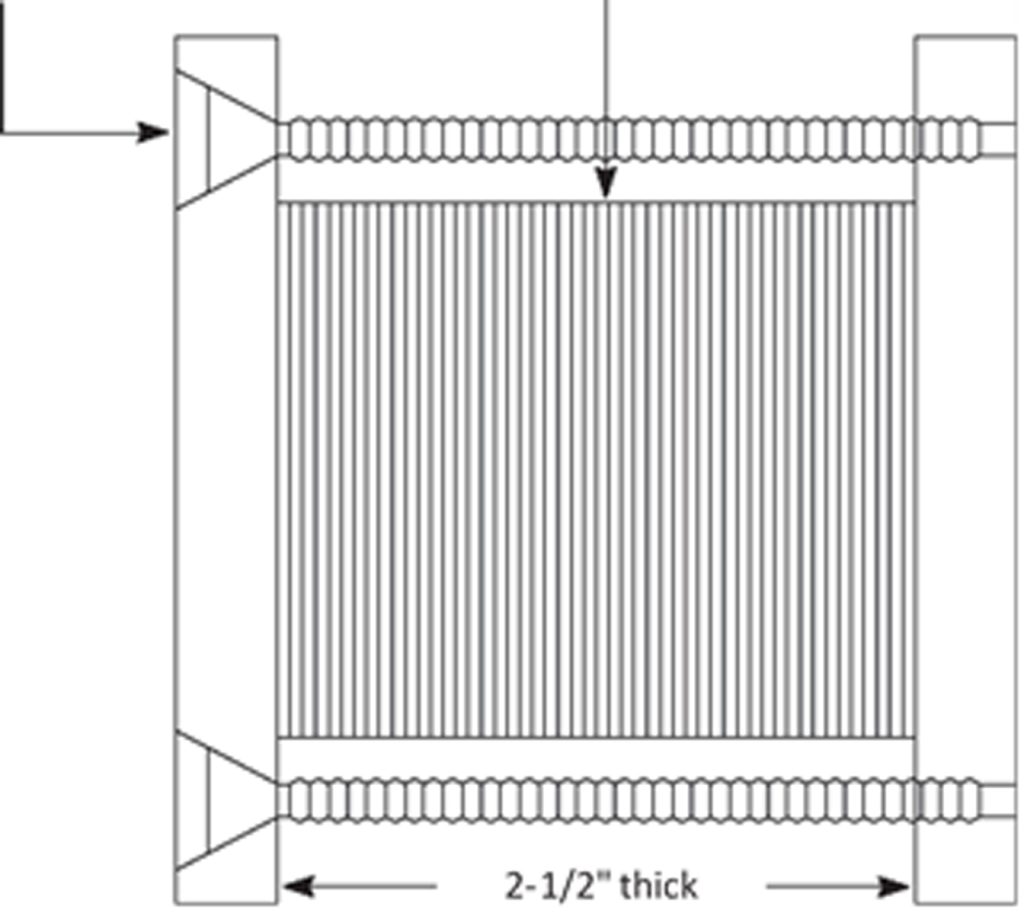

Usually the machining costs are determined by the amount of square inches of cutting, Other factors are type of material, programming, set up time, and whether the flushing nozzles contact the part. It should be noted that thickness of materials can have a dramatic effect on cutting speeds. When manufacturers quote their cutting speeds, they use their optimal height, around 2 1/4″ (57 mm). Taller pieces cut significantly slower.