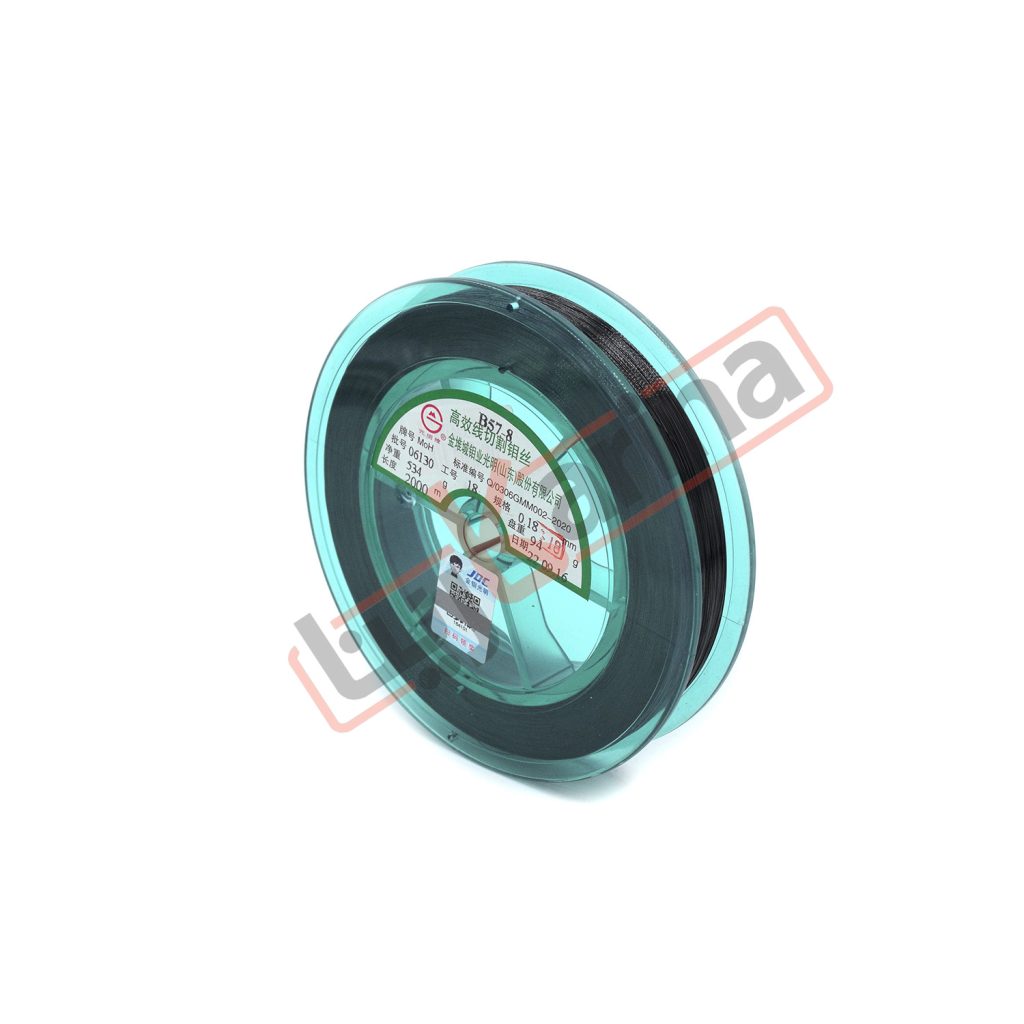

Karina Ideal Equipment Company is a provider of molybdenum wire cutting tools with the highest quality. Types of molybdenum wirecut wire in diameters of 0.18, 0.2 and… can be provided for use in wirecut cutting machine as one of the edm (electrical discharge machining) methods. Wirecut wire provided by this company is provided directly from the main manufacturer and with the highest quality. These wires are rolled and provided in a standard length of 2000 meters. It should be noted that most of the wirecut wires available in the market, which are mainly made from unreliable Chinese manufacturers, have lower quality and shorter length than the standard. But the molybdenum wirecut wire provided by this company has the highest quality and completely standard size. Wirecut wire is made of molybdenum, which has a 30% longer life compared to similar samples.