Faster Machining Speed – Newer oils are highly refined and refined to be more efficient. They are designed to burn off cleaning agents, so they produce a finer surface more quickly.

Less Smoke – Smoke from high amp burns can produce large amounts of toxic smoke that must be vented outside. Even then, what happens to the smoke?

Longer fluid life – Because the electric discharge machining enables it to be more efficient, heat and sludge don’t break down the oil as quickly. This can mean savings in materials and time.

Easy on the skin – Many operators complain of skin irritation from older kerosene-based fluids. Wirecut’s new synthetic oils are much easier on the skin.

It doesn’t evaporate – your oil will last longer and your shop won’t smell like a diesel engine repair shop.

Environmentally friendly, because the new wirecut oils are synthetic, they are much easier to dispose of and have less impact on the environment.

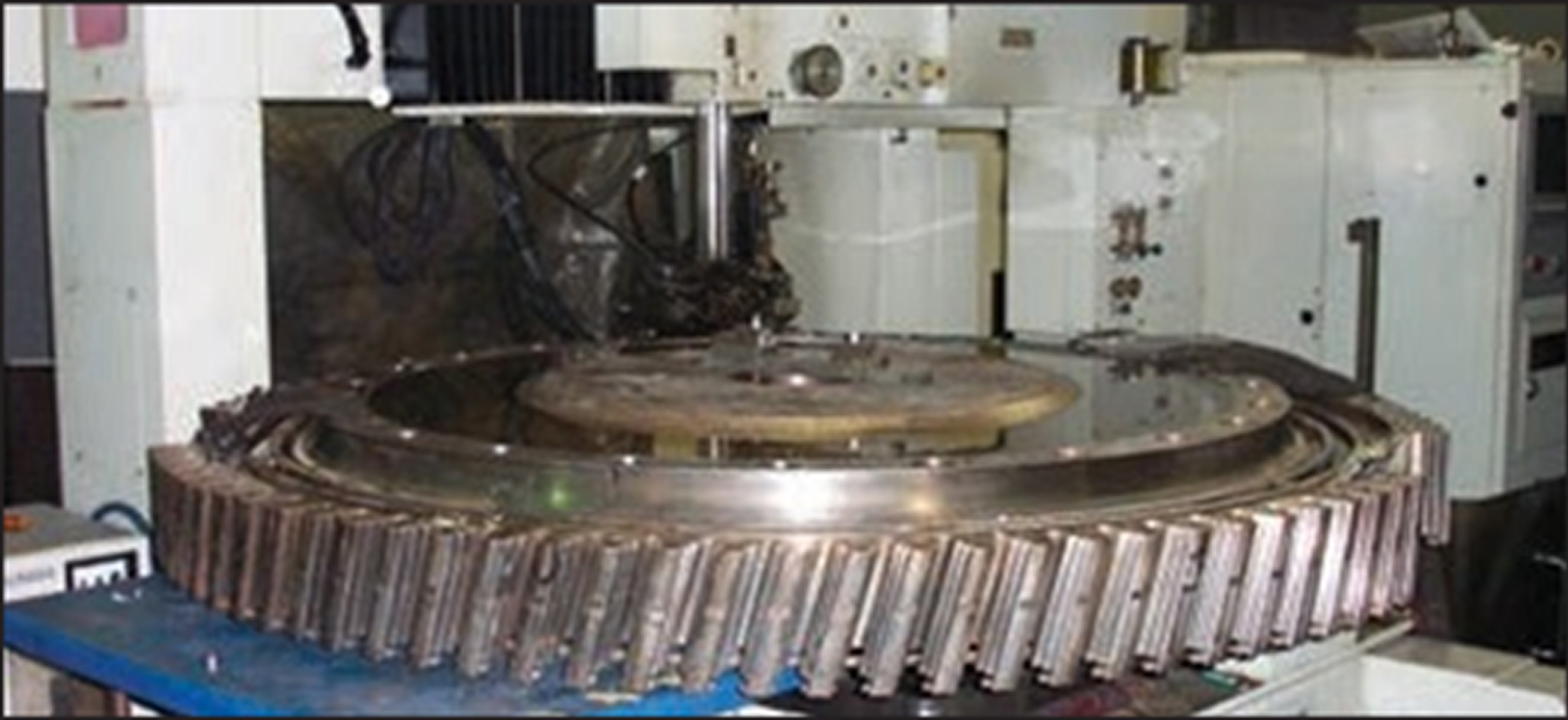

You only get one chance to make a good first impression

Choosing the right wirecut oil can make a significant difference in the overall performance of your wirecut. Buying good wire cutting equipment makes sense any way you look at it.