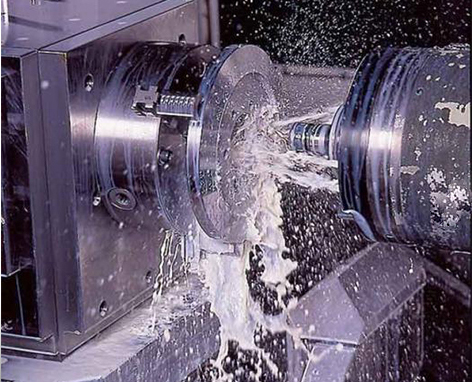

As you know, oil does not dissolve in water. When oil is added to water, its particles are suspended in the form of tiny droplets. Oil is broken into very small particles by a chemical compound called an emulsifier. A solution of oil in water is called an emulsion.

In fact, soapy water or emulsifying oil is a mixture of a type of base oil and emulsifier with other additives, which include antibacterial, anti-corrosive, anti-foam, etc. Soaps are among water-miscible oils that are used as emulsions. This oil is easily mixed with water in different proportions and forms a milky and homogeneous mixture.