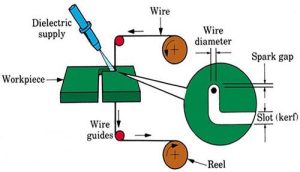

A EDM Wirecut is a device that creates a cut on the work piece with a thin wire (usually 25 microns) placed inside the dielectric liquid (distilled water). The thermoelectric energy creates a quick spark between the work piece and the wire, causing a momentary “Burning Away” melting of this point. The process of melting is done inside a dielectric liquid. The role of the dielectric is cooling, washing and keeping the wire vertical. The material of the workpiece can be soft such as aluminum, copper and brass to hard steel and even tungsten carbide (diamond).

This spark is visible and when the water is clean, the removal of micron chips is clearly visible.

This is what makes wirecut unique because there is no physical contact between the wire and the workpiece and there is always a gap (GAP) between the wire and the workpiece. Therefore, the tool error is low and as a result, the accuracy increases.

The role of the wirecut wire is to transmit the spark and it must have good conductivity and sufficient strength.

In general, there are two types of wires that are used and return. Wires used in wire cutting are made of copper or brass with different coatings of zinc and zinc oxide. Recently, Korea, Taiwan and China have provided good products. These wires with different tensions are usually used <500-900 newtons per meter and due to spark wear and size loss, they are only used once. Reciprocating wires are mainly molybdenum and tungsten compounds and are usually used in Chinese machines.

The geometry of the part to be cut is usually drawn in a cross-section, often in AutoCAD or Corel Draw. This drawing is saved in (DWG) or (DXF) format. This file is opened in ESPIRIT software and it is converted into NC or ISO file according to lines, arcs and circles as a left or right orbital path. This is a text file and the basis of this file’s work is G-Code, which converts existing shapes into lines and arcs, and this is the same machine language.

Three main commands are the basis of this language:

And these movements are performed according to the mandrel command {(necessary middle part) with offset from outside} or matrix {(necessary outer part) with offset from you} automatically taking into account wire diameter and spark gap.

The verticality of the wire is very important in a wirecut machine, and this work is done automatically in a modern CHARMILLES machine with a simple and interesting geometric method, and by obtaining the center of the eye at different heights, it aligns the upper and lower guides completely. . To create the angle of the two axes X-axis and Y-axis, the above head is added, and by changing the values of these axes, the desired angle is obtained.

Switzerland, Japan and Spain are among the most important manufacturers of this device, and recently Taiwan and China. Although Japanese wirecuts such as Mitsubishi, Sodic, Fanuc are good in their own way and use interesting initiatives, they have not enjoyed much success in Iran, and the reason is the acceptance of Swiss-made wirecuts, especially CHARMILLES, by Iranian craftsmen.

These wirecuts entered Iran in the 1990s with the 100 series models. Due to good accuracy, simplicity of work and high efficiency, ease of repair and availability of parts and good and skilled service, they have been noticed. Although the new series of this factory is one of the masterpieces of European industry and design, they are less available in Iran due to reasons including the high price.

One of the special advantages of wirecut is the basis of work in the form of electric discharge.

With this method, the spark is not like a pressure on the workpiece and machine axes, and this machine moves micron by micron, and as long as it takes command from its computer, it moves without any error. With this advantage, it is possible to design and implement all kinds of precise parts and step molds of mandrel, matrix and plastic. For example, in step molds, the capability of wire cutting cannot be compared with other devices, even CNC milling, because it cuts the same length and height. This ability cannot be seen in any of the CNC milling or turning machines.

The complexity and abundance of wirecut systems, while making investment costs more expensive, causes sensitivity in the work of this device and causes high maintenance costs. So that all the following systems must be constantly controlled and serviced and occasionally replaced. The slightest procrastination will cause big problems later.

While using wirecut abilities, the operator must master the part and master the device controller.

Neglecting the smallest point will cause the loss of the part and damage.

This feature requires an intelligent, precise, insightful, enthusiastic and trained operator.

The cutting of micron particles causes permanent deposits in all tanks and corrosion of the moving axes of the device.

Although by filtering the water, these particles are taken from the water flow path and collected in the filter holes, but depending on the device, some particles are always deposited in different places and cause trouble.

Due to the transfer of water pressure in the cutting channel and higher machining speed

The guide and the top nozzle should be close to the piece, so we don’t have a direct view of the piece.

Therefore, to avoid possible errors, we are deprived of direct control.

Constant water has caused clogging of channels, stone deposits, leakage and clogging of pipes and chamfer holes

And they should definitely be checked and serviced at certain times and possibly replaced.

Electrical conductivity Electro Conductivity = E.C. which increases regularly due to the release of metal ions suspended in the water of the device (distilled water C = 0 at first to the allowed vicinity (E.C = 35), although mixed resin (cationic and anionic mixture) is used to reduce the ions It is possible. But this resin is consumable and expensive and must be replaced regularly. If the E.C. increases while the parts rust, the cutting speed will decrease and it will cause the wear of many parts.

Another disadvantage of the machine is its low machining speed, which cannot compete with CNC or laser and waterjet milling.

Although today’s modern devices have become faster, they have limited economic competition due to their high price.