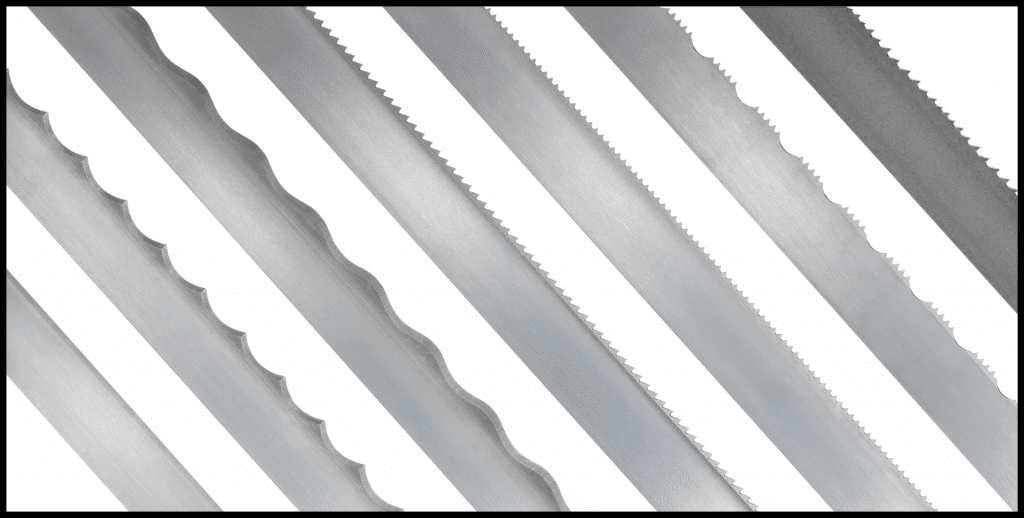

Among the other elements that affect cutting and include choosing the right band saw blade are the teeth. We are not just talking about the size and shape of the teeth. The most important aspect of band saw teeth is the number of teeth per tooth (TPI).

Determining the right TPI leads to the right feed rate and the right finish. A general rule to follow is that the more teeth per inch of the blade, the finer the cut. The feed rate will be slow, but also very smooth. Fewer teeth per inch means a faster feed rate and a rougher cut.

The three common shapes of band saw blades are: regular, hook, and skip.

Conventional tooth blades are the most popular because of their straight teeth, deep grooves and even spacing. Used for general sawing purposes, you can perform cut or contour sawing on thin sheet metal. These blades have a rake of 0 degrees (straight).