There is a band saw in the production line in a continuous form and in the beginning in the form of a coil. So, considering the used saw machine, cut a specific length of it. and welded its two ends together. to form a ring. By welding the band saw blade, the blades can be shaped to desired sizes.

Due to the fact that the sizes of the band saw blade have many variations. Companies producing band saw blades produce their products in rolls of 30, 50, 75, 100 and 130 meters. Then finally, for consumption, the band saw blades should be cut and welded according to the size of the consumer. Manual scissors are usually used to cut the band saw blade. And to weld it, due to the bimetallic nature of the band saw blade, you must definitely use advanced band saw blade welding devices.

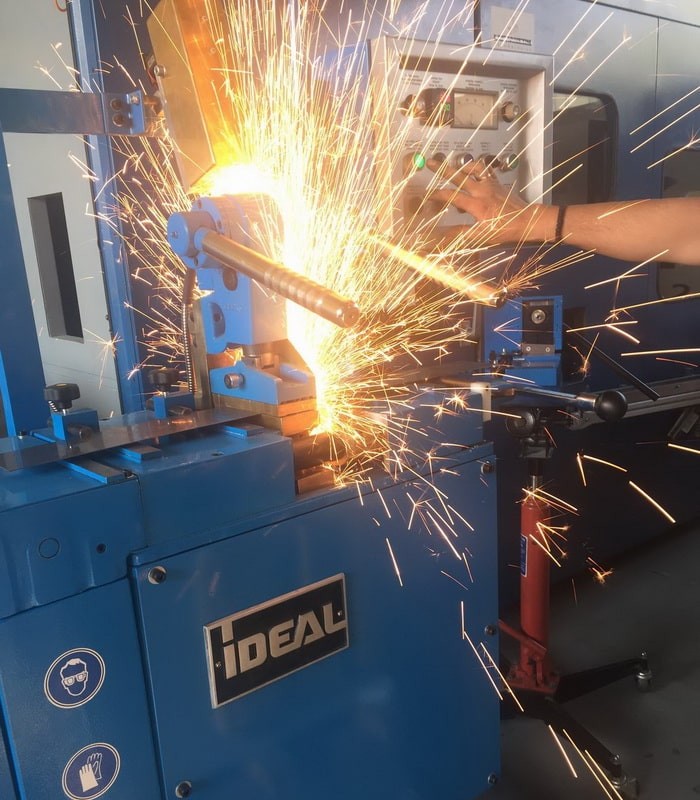

The blade welding machine performs the welding process through butt welding. In this method, you first place the two ends of the bandsaw blade facing each other in a way that they are in the same direction and at the same height. After placing the two ends of the band saw blade facing each other, one of the machine’s jacks creates a small gap between the two ends of the saw blade. so that the induction current produced by the electrodes of the device passes through the empty space between the two ends of the blade and causes an electric arc and the two ends of the blade become paste. After the two ends of the saw blade are kneaded, one of the hydraulic jacks squeezes the two ends of the blade together. to mix with each other.

After the welding operation is finished, the device anneals the welding area twice to increase the flexibility and tensile strength of the blade. Finally, the appendage created from the welding site should be removed. And the welding place should be the same level as the body of the band saw blade. In some welding machines, this operation is performed automatically by the machine itself. And in devices that do not have this method, a grinding device should be used to remove the appendage.

Welding services and repairs of blades and band saw machine provided by Amakat Group are as follows.

– Welding all types of band saw blades in widths of 6-13-20-27-34-41-54-67

– Annealing operation of all kinds of band saw blades in different widths

– Specialized repairs of all types of damaged band saw blades (broken teeth, falling teeth, etc.),

– Covering the tips of the teeth to prevent damage to the teeth and safe transportation

– Repairs of all types of band saw machines with full guarantee